This resource was published on 5 November 2020

The third session of the 2020 PSCI china supplier conferences took place virtually on 15 October and covered ethics, human rights & labor.

2020 PSCI线上供应商会议(中国)第三场在10月15日举行,会议内容包括商业道德、人权及劳工。

The recording is available here (code:PSCI).

会议视频请点击此 链接 获取 (提取码 PSCI)。

Slides are available for download below.

会议PPT请在下方点击“DOWNLOAD”下载。

Recordings and slides of individual presentations are available as individual resources - please click on the relevant links below:

每个环节单独的视频和PPT也上传至本网站。请点击下列相关链接获取:

-

Ethics

-

Human Rights & Labor

This resource was published on 3 November 2020

The third session of the 2020 PSCI India supplier conferences took place virtually on 15 October and covered Ethics, Human Rights & Labor.

The full recording of the session is available here. Slides are available for download below.

Recordings and slides of individual presentations are also available as individual resources - please click on the relevant links below:

-

Ethics

-

Human Rights & Labor

This resource was published on 3 November 2020

This presentation on Operationalizing the PSCI Human Rights Principles was delivered by:

- Samah Abbasi, Human Rights Manager, GSK

- Peter Nestor, Human Rights Manager, Novartis

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 3 November 2020

This presentation on A Conversation on Forced Labor and Modern Slavery was delivered by:

- Laura Greene, Program Technical Officer, ILO Global Business Network on Forced Labour

- Peter Hall, Senior Manager Human Rights & Sustainability Compliance, Johnson & Johnson

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 3 November 2020

This presentation on Introduction to PSCI Principles & Antibribery and Corruption was delivered by:

- Sumit Makhija, Financial Advisory Services Forensic Partner, Deloitte

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

-

Ethics

-

Human Rights & Labor

This resource was published on 3 November 2020

This presentation on Introduction to GDPR was delivered by:

- Helene Millenaar, Global Risk and Compliance Director, Centrient Pharmaceuticals

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 22 October 2020

This presentation on Case studies on WWT technology was delivered by:

此演讲由下列嘉宾分享PiE:废水处理技术案例

- Ken Sun, EHS&S Lead -Third Party, GSK | 孙大勇,第三方EHS&S主管,葛兰素史克

- Wenjun Wang, Senior EHS Manager, Pfizer Global Environment, Health and Safety | 王文君, 高级EHS经理,辉瑞

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

-

Environment

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 22 October 2020

This presentation on EWhole effluent toxicity (WET) testing methods and application was delivered by:

此演讲由下列嘉宾分享全废水毒性测试方法与应用:

- Xiaoqian Chen, Senior Engineer, Bioassay and Safety Assessment Laboratory, Shanghai | 陈晓倩, 高级工程师, 上海市检测中心 生物与安全检测实验室

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

-

Environment

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 22 October 2020

This presentation on How to do a mass balance calculation was delivered by:

此演讲由下列嘉宾分享生态环境中药物活性成分的总量平衡计算 :

- Ken Sun, EHS&S Lead -Third Party, GSK | 孙大勇,第三方EHS&S主管,葛兰素史克

- Wenjun Wang, Senior EHS Manager, Pfizer Global Environment, Health and Safety | 王文君, 高级EHS经理,辉瑞

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

-

Environment

-

Pharmaceuticals In The Environment

This resource was published on 22 October 2020

This presentation on Environmental hazards of drugs and case analysis was delivered by:

此演讲由下列嘉宾分享药物的环境危害与案例分析 :

- Min Liu, Head of Tech, Bioassay and Safety Assessment Laboratory, Shanghai | 刘敏, 技术总监, 上海市检测中心 生物与安全检测实验室

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

-

Environment

-

Pharmaceuticals In The Environment

This resource was published on 22 October 2020

This presentation on sustainable packaging was delivered by:

此演讲由下列嘉宾分享可持续包装:

- Zelia Kranich, Sustainable Sourcing Associate Director, Merck & Co., Inc. | Zelia Kranich, 可持续副总监, 默沙东

- Victor Bell, US Managing Director, Lorax EPI | Victor Bell, 美国常务董事, Lorax EPI

- Jacqueline Hollands, Global Manager, Customer Sustainability Solutions, MilliporeSigma | Jacqueline Hollands, 客户可持续发展解决方案全球经理,密理博西格玛

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 22 October 2020

This presentation on taking climate action was delivered by:

此演讲由下列嘉宾分享应对环境变化主题:

- Maggie Zhang, Partner Manager, Carnstone | 张缤莉, 合伙人经理,凯嵘管理咨询

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

-

Environment

-

Decarbonization

This resource was published on 22 October 2020

This is the opening address of the PSCI Virtual China Supplier Conference 2020, delivered by:

此会议内容为PSCI 环境工作小组简介,我们很开心能够邀请两位嘉宾出席:

- Rikke Christensen, Head of Sustainable Procurement, LEO Pharma | Rikke Christensen, 可持续采购负责人, 利奥制药

- Zelia Kranich, Sustainable Sourcing Associate Director, Merck & Co., Inc. | Zelia Kranich, 可持续副总监, 默沙东(在美国和加拿大称为默克公司)

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code:PSCI). The slides are available for download below.

会议视频请点击此 链接 获取 (提取码 PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 22 October 2020

The second session of the 2020 PSCI China supplier conferences took place virtually on 24 September and covered Environment, Pharmaceuticals in the Environment/AMR.

The full recording of the session is available here (code:PSCI). Slides are available for download below.

Recordings and slides of individual presentations are also available as individual resources - please click on the relevant links below:

2020 PSCI线上供应商会议(中国)第二场在9月24日举行,会议内容包括环境,环境中药物残留及抗微生物药物耐药性。

本次会议的完整视频请点击链接 获取 (提取码 PSCI) 获取会议视频。会议PPT请在下方点击“DOWNLOAD”下载。

每个环节单独的视频和PPT也已上传至本网站。请点击下列相关链接获取:

-

Environment

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 9 October 2020

The first session of the 2020 PSCI China supplier conferences took place virtually on 17 September and covered PSCI Updates and Management Systems.

The full recording of the session is available here (code: PSCI). Slides are available for download below.

Recordings and slides of individual presentations are also available as individual resources - please click on the relevant links below:

2020 PSCI线上供应商会议(中国)第一场PSCI最新发展和管理体系的完整视频在此链接 获取。 (提取码 PSCI)。会议PPT请点击下方“DOWNLOAD”下载。

每个环节单独的视频和PPT也已上传至本网站。请点击下列相关链接获取:

This resource was published on 9 October 2020

This presentation on PSCI capability building vision and plans was delivered by:

此演讲由下列嘉宾分享PSCI 供应商能力建设愿景和规划:

- Lamy Bao, EHS Associate Director External Manufacturing, Bristol-Myers Squibb | 鲍国祥,内外部环境健康安全审计总监,百时美施贵宝制药

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此 链接 (提取码:PSCI) 获取会议视频。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 9 October 2020

This is the opening address of the PSCI Virtual China Supplier Conference 2020, delivered by:

此会议内容为PSCI和本地团队欢迎所有会议参议者,我们很开心能够邀请两位嘉宾出席:

- Caroline O'Brien, Asia Pacific Director of Global Audit Quality, AstraZeneca, and PSCI Chair | Caroline O'Brien, 全球质量审计-亚太区总监, 阿斯利康, PSCI 主席

- Yi Zhang, EHS&S Manager External Supply Chain, Johnson & Johnson, and PSCI China Sub-Team Co-Lead | 张怡,EHS&S外部供应商经理,强生(中国)

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此 链接获取(提取码:PSCI) 。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 9 October 2020

This presentation on the future of online learning was delivered by:

此演讲由下列嘉宾分享线上学习主题:

- Professor Diana Laurillard, Professor of Learning with Digital Technologies, UCL Institute of Education

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此链接 (提取码:PSCI) 获取。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 9 October 2020

This presentation detailing our audit finding analysis was delivered by:

此演讲由下列嘉宾分享PSCI 共享审计发现研究:

- Lei Jiang, EHS Senior Director, STA Pharma | 蒋磊, 高级环境健康安全总监, 合全药业

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此链接 获取(提取码:PSCI)。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 9 October 2020

This presentation introducing Pharmaron’s work arrangement, prevention and control organization, and normalized control in the fight against COVID-19 was delivered by:

此演讲由下列嘉宾分享康龙化成的新冠疫情防控经验:

- Liuqian Ni, EHS Specialist, Pharmaron | 倪柳倩, 环境健康安全专员, 康龙化成(北京)

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此链接获取(提取码:PSCI) 。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 9 October 2020

This presentation sharing the key points from China’s “Measures for Environmental Management Registration of New Chemical Substances” was delivered by:

此演讲由下列嘉宾介绍中国新化学物质环境管理办法的最新进展:

- Lingzhen Dong, Asia Pacific Region -Product Stewardship Director, Johnson & Johnson | 董玲珍,亚太区EHS&S产品监管总监,强生(中国)

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此链接 获取 (提取码:PSCI) 获取会议视频。会议PPT请在下方点击“DOWNLOAD”下载。

-

Management Systems

-

Chemical Registrations

This resource was published on 9 October 2020

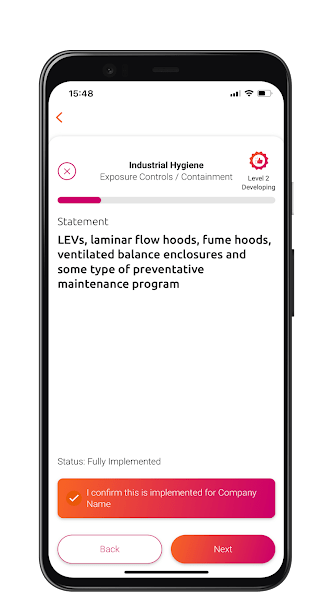

This presentation on PSCI Management System Maturity Model was delivered by:

此演讲由下列嘉宾分享PSCI 管理系统成熟度模型:

- Kelley Jiang, Head HSE Supplier Assurance & Risk – China Region, Novartis | 江戎, 大中国区供应商健康安全环境风险管理主管, 诺华

This session was facilitated by Maggie Zhang, Partner Manager at Carnstone.

本环节由凯嵘管理咨询合伙人经理张缤莉主持。

The recording is available here (code: PSCI). The slides are available for download below.

会议视频请点击此链接获取 (提取码:PSCI) 。会议PPT请在下方点击“DOWNLOAD”下载。

This resource was published on 5 October 2020

The primary focus of this document is to provide a consistent guidance for pharmaceutical companies to calculate GHG emissions in their upstream and downstream value chains. It provides methodologies consistent with recommendations from the GHG Protocol for calculating emissions which are tailored for each different category.

This document was developed by the Pharmaceutical Environment Group (PEG) and its participating companies, who have kindly shared it with the PSCI for diffusion.

-

Environment

-

Decarbonization

This resource was published on 2 October 2020

This presentation on the future of online learning was delivered by:

- Professor Diana Laurillard, Professor of Learning with Digital Technologies, UCL Institute of Education

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

This presentation on PSCI Management System Maturity Model was delivered by:

- Roberta Haski, HSE, External Manufacturing, Asia Pacific, Elanco

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

This presentation on Indian Case Study on Controlling API Releases Including Wastewater Treatment/Analysis was delivered by:

- Jon Peers, Director of Environment, Teva

This session was facilitated by Annabel Buchan, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

-

Environment

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 2 October 2020

This introduction to sampling and analysing APIs in wastewater was delivered by:

- Jon Stanway, Biotechnology & Environmental Downstream Manager, GSK

This session was facilitated by Annabel Buchan, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

-

Environment

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 2 October 2020

This presentation on Draft Indian Wastewater Standards - Current Status and Possible Ramifications for Indian companies was delivered by:

- Mugundan Ramachandran, Senior Consultant, ERM India Private Limited

- Shivananda Shetty, Partner & Commercial Director, ERM India Private Limited

This session was facilitated by Annabel Buchan, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

-

Environment

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 2 October 2020

This presentation on Sustainable Packaging was delivered by:

- Jacqueline Hollands, Global Manager, Customer Sustainability Solutions, MilliporeSigma

- Victor Bell, US Managing Director, Lorax EPI

- Zelia Kranich, Sustainable Sourcing Associate Director, Merck & Co., and PSCI Environment Sub-Team Co-Lead

This session was facilitated by Annabel Buchan, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

This presentation on Taking Climate Action was delivered by:

- Glynn Roberts, Director and Senior Partner, Carnstone

This session was facilitated by Annabel Buchan, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

-

Environment

-

Decarbonization

This resource was published on 2 October 2020

This PSCI Environment Sub-Team Overview was delivered by:

- Rikke Christensen, Head of Sustainable Procurement, LEO Pharma, and PSCI Environment Sub-Team Co-Lead

- Zelia Kranich, Sustainable Sourcing Associate Director, Merck & Co., and PSCI Environment Sub-Team Co-Lead

This session was facilitated by Annabel Buchan, Partner Manager at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

The second session of the 2020 PSCI India supplier conferences took place virtually on 24 September and covered Environment and Pharmaceuticals in the Environment/AMR.

The full recording of the session is available here. Slides are available for download below.

Recordings and slides of individual presentations are also available as individual resources - please click on the relevant links below:

This resource was published on 2 October 2020

This presentation on Safety Culture was delivered by:

- Raju Ingale, Senior Director EHS&S Asia Pacific, Johnson & Johnson

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

-

Health & Safety

-

Management Systems

This resource was published on 2 October 2020

This presentation on India Chemical Management & Safety Rules (ICMSR) was delivered by:

- Jayachandran Nair, CEO, Global Product Compliance (GPC) India

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

-

Health & Safety

-

Management Systems

-

Chemical Registrations

This resource was published on 2 October 2020

This presentation on learnings from responding to Covid-19, an experience sharing from Pfizer, India was delivered by:

- Ranjana Ganguly, Global EHS Leader - India and Pakistan, Pfizer

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

This presentation detailing our audit finding analysis was delivered by:

- Shelly Shope, HSE Advisor, Elanco, and PSCI supplier capability committee co-chair

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

This presentation on PSCI capability building vision and plans was delivered by:

- Ingrid Vande Velde, Senior Manager EHS&S External Supply EMEA/ASPAC, Johnson & Johnson and PSCI Supplier Capability Committee co-lead

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

This is the opening address of PSCI Virtual India Supplier Conference 2020, delivered by:

- Caroline O'Brien, Asia Pacific Director of Global Audit Quality, AstraZeneca, and PSCI Chair

- Manjit Singh, Associate Director of Corporate Sustainability, Centrient Pharmaceuticals, and PSCI VIce-Chair and Chair of the India Sub-Team

This session was facilitated by Simon Hodgson, Managing Partner at Carnstone.

The recording is available here. The slides are available for download below.

This resource was published on 2 October 2020

The first session of the 2020 PSCI India supplier conferences took place virtually on 17 September and covered PSCI Updates and Management Systems.

The full recording of the session is available here. Slides are available for download below.

Recordings and slides of individual presentations are also available as individual resources - please click on the relevant links below:

This resource was published on 14 September 2020

The webinar explored best practice wastewater treatment methods for managing the release of APIs into the environment from pharmaceutical manufacturing sites. It was delivered by renowned experts and featured case studies on novel treatment technologies.

We were delighted to be joined by the following speakers:

- Jeffrey Brenchley from Merck (MSD) (Senior Specialist, Global Safety & Environment), speaking about vacuum evaporation

- Birgit Mertens from Johnson & Johnson (Senior Principal Environment Worldwide EHS&S), speaking about ozone as pretreatment

- Jonathan Rhone from Axine Water Technologies Inc. (President and CEO), speaking about electrochemical oxidation

Participants are invited to share feedback about this webinar here.

The recording is available here. (Please refresh the page if you cannot play the video.)

The slides used during the webinar are available to download below.

Please also note that registration for the second session of our supplier conferences is open until 17 September. Topics covered will include climate change (GHG) & sustainable packaging ; sampling and analysing APIs in wastewater with case studies ; a case study on Controlling API Releases; environmental hazards of drugs and case analysis ; and mass balance calculations. To register, please click here for the China session and here for the India session.

Finally, we want your views! We're encouraging all suppliers to take this short survey to help the PSCI understand the impact it has on suppliers.

-

Spills & Releases

-

Waste Management

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 3 September 2020

The agenda for China conference is updated on 10 September 2020. Please select the language that you prefer to use before downloading it.

下载会议议程前请先选择语言:英文、简体中文。

This resource was published on 3 September 2020

This draft agenda for India conference is updated on 9 September 2020.

This resource was published on 2 July 2020

The PSCI has recently published its Summer newsletter, reflecting on achievements in the first half of 2020 and looking ahead at a busy programme of exciting events and projects for the rest of the year.

Download the newsletter below to read about our efforts to digitalize our offer to suppliers, our position on important issues such as PiE/AMR, and the partnerships we’re forming with Indian and Chinese organizations. You’ll also find updates on PSCI audit findings from the past three years, our take on emerging issues in supply chains – and more!

This resource was published on 8 June 2020

This webinar first aired on 27 May and explained the updates and changes to the Audit Guidance document. We were delighted to be joined by the following speaker:

- Birgit Skuballa, from Bayer

The webinar attracted over 100 registrants and around 90 people joined on the day.

Participants are invited to share feedback about this webinar here.

The recording is available here.

The slides used during the webinar are available to download below.

Finally, we want your views! We're encouraging all suppliers to take this short survey to help the PSCI understand the impact it has on suppliers.

This resource was published on 27 April 2020

We are very pleased to announce that the PSCI 2019 Annual Report is now available, summarising our collective efforts towards responsible supply chains during 2019.

Key developments in 2019 include:

- Growth in membership, with today over 40 member companies.

- Hundreds of audits completed to PSCI standards now available to members on our new community platform The Link, alongside valuable resources, news, and training materials.

- Unprecedented levels of supplier engagement through two large-scale supplier conferences in Hangzhou (China) and Hyderabad (India), reaching 400 supplier delegates.

- New Partnerships Committee focused on intensifying our relationship with our Indian and Chinese partners.

- Expansion of our expert advisory panel, now composed of eight external experts who challenge and advise the Board.

- Measured improvement in PSCI member companies’ public reporting of supply chain data and commitment to PSCI’s Principles.

In 2020, much of business will be operating in a changed environment. It remains to be seen exactly how this will affect the industry and our supply chain practices. Our focus on efficient sharing of audits and virtually-enabled capability building activities is even more important in the wake of Covid-19. Whatever changes arise from this crisis, responsible supply chain practices will be central to our industry’s response.

We welcome comments and encourage you to share this report with your networks.

This resource was published on 20 April 2020

This announcement provides more information about our supplier community platform, providing more information on why suppliers should engage.

This resource was published on 19 April 2020

MS Word version

PSCI Self Assessment Questionnaire and Audit Report Template for Core Suppliers, External Manufacturers, Component and Material Suppliers

More Info…

Update History

Version 5, February 2019

Chinese translation added July 2019.

Japanese translation added April 2020.

Remote audit options added November 2020.

Since 20 April 2022, the Word versions of the templates (Full, Abbreviated, CAPR) have been removed completely following a consultation process and notice period. Access to these is only be possible in exceptional circumstances and by contacting the PSCI Secretariat. Please use the Excel versions: Full, Abbreviated, CAPR

-

Ethics

-

Human Rights & Labor

-

Health & Safety

-

Environment

-

Management Systems

-

Audit Program

This resource was published on 27 March 2020

On behalf of the Board and Communications Committee and with thanks to the Pharmaceuticals in the Environment (PiE)/ Anti-Microbial Resistance (AMR) sub-team for their expert input, we are sharing the recently adopted PSCI Position Statement on PiE & AMR. It has been written to highlight the relevance of the PiE issue along the supply chain, to articulate PSCI's position on this high profile topic, and to help answer stakeholder inquiries. It includes an overview of all PSCI resources on PiE and AMR-related issues.

-

Pharmaceuticals In The Environment

-

Anti-Microbial Resistance

This resource was published on 25 March 2020

This document can be used by suppliers to document agreed corrective actions, the type of finding(e.g. Critical-Other, Critical-Major/Minor), the time period for completion, the type of verification (e.g. desk top review of documents or follow up visit), the responsible individual at the supplier for the individual corrective actions, details on the implemented corrective action and a status assignment (open/closed).

Since 20 April 2022, the Word versions of the templates (Full, Abbreviated, CAPR) have been removed completely following a consultation process and notice period. Access to these is only be possible in exceptional circumstances and by contacting the PSCI Secretariat. Please use the Excel versions: Full, Abbreviated, CAPR

This resource was published on 3 March 2020

Supplier Data Sharing Agreement (Last updated March 2024).

A Chinese version is now available.